Showing 25–36 of 56 results

-

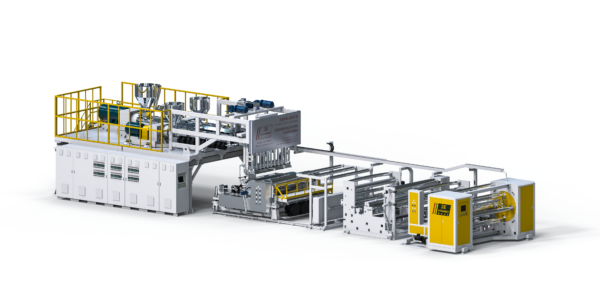

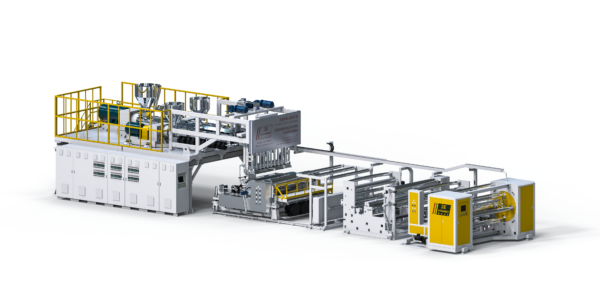

1. Equipped with a positive pressure device to ensure the stability of the film

2. The film online recycling device greatly reduces production costs

3. Fully automatic central rolling, equipped with servo wheel controller, automatic roll changing and cutting, easy to operate

-

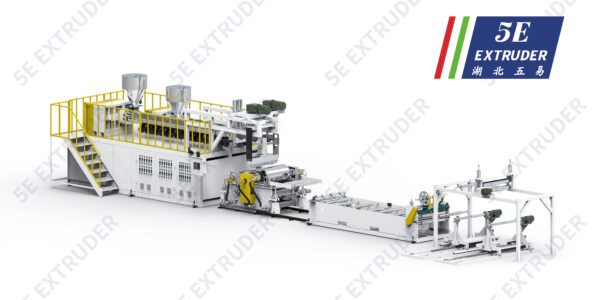

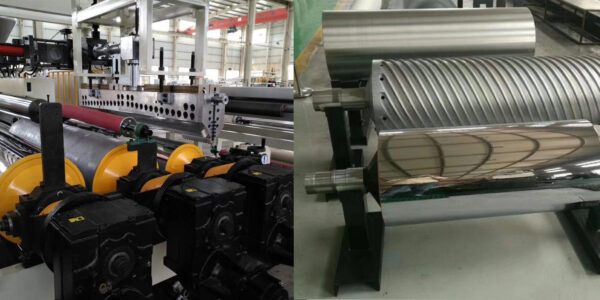

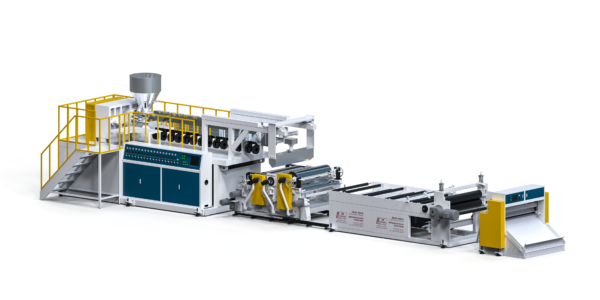

1. The screw is designed with a special mixing function and high plasticizing capacity, which is matched with a European static mixer to ensure good plasticization, good mixing effect, and high output

2. Online auto film-thickness measurement and automatic die-head adjusting, imported Europe cooling forming roll is optional, and the special spiral runner design ensures good film cooling and shaping effect at high speed

-

- Blow-up ratio: 1:5

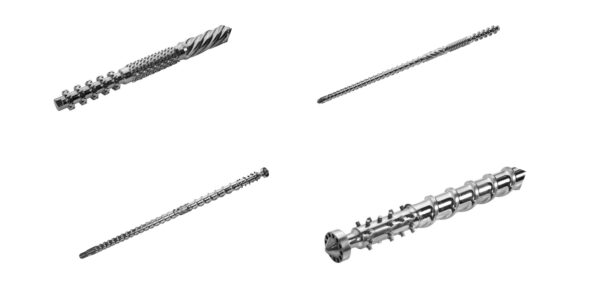

- The structure of a step-less variable speed reduction gearbox is simple and can be equipped with V.S Motor or DC motor or variable frequency motor according to the customer’s needs to adjust the screw speed at will.

-

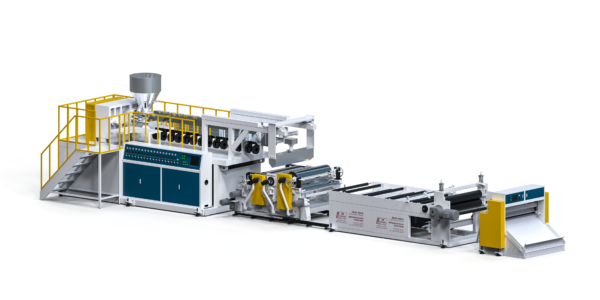

The machine can effectively use the proportion of stone powder, which not only reduces the cost of raw materials but also improves the degradability of sheets and ensures the comprehensive physical properties and subsequent processability of sheets.

-

1. Blow-up ratio: 1:2.5

2. The structure of a step-less variable speed reduction gearbox is simple and can be equipped with V.S Motor or DC motor or variable frequency motor according to the customer’s needs to adjust the screw speed at will

-

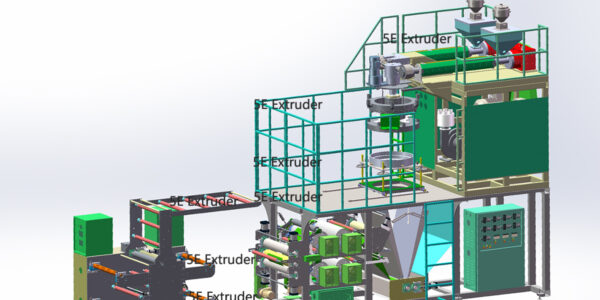

1. Interlocking safety design ensures the safety of operators

2. Equipped with three screws and an optimized combination of the aspect ratio

3. Speed frequency conversion control and touchscreen control

4. Equipped with three in one water tank to save energy and reduce consumption

5. The cutting table adopts a servo motor and swing bar structure to ensure accuracy and speed

-

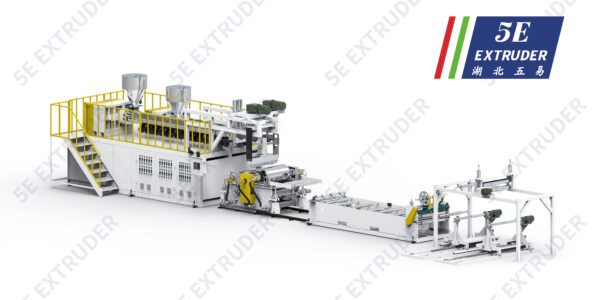

PP PE PS extrusion line has the advantages of high output, good plasticization, convenient operation, and stable operation.

-

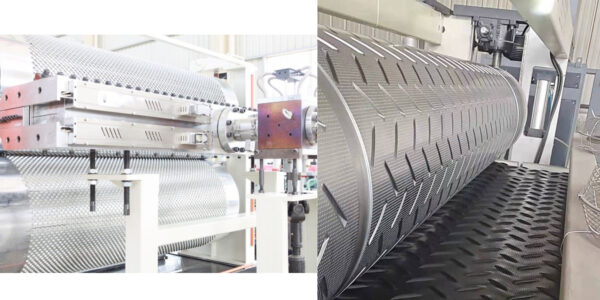

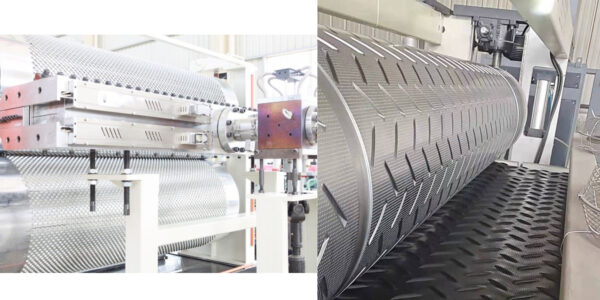

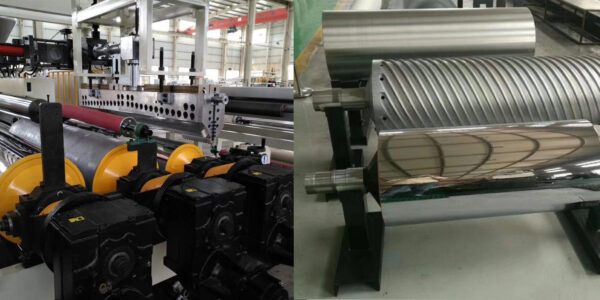

The pattern roller is used for the surface forming treatment of various plastic sheets and plates such as PMMA, PC sheet, PP sheet, etc. The roller surface can be processed into various patterns. The laser electronic scanning and color separation technology is used to convert the customer’s sample image into high-definition digital image information, which is directly input into the engraving machine to copy and carve high-quality roller surface patterns.

-

1.Double shell, internal spiral flow channel design, with good heat dissipation efficiency.

2.The hot fitting interference fit is adopted, with high roller strength; Medium high compensation bending to reduce the thickness error of sheet and plate products.

-

The application of the screw chiller to the cooling of the plastic processing machinery molding mold can greatly improve the surface clarity of the plastic products, reduce the surface wrinkles and internal stress of the plastic products, make the products not shrink and deform, facilitate the demolding of the plastic products, accelerate the product shaping, and greatly improve the production efficiency of the plastic molding machine.

-

Features of screw feeder:

Spindle speed: 400 rpm

Working capacity: 300KG – 3000KG/hour

The individual feeding height of this series of machines: 2-5m, and multiple machines can be applied for connection.

-

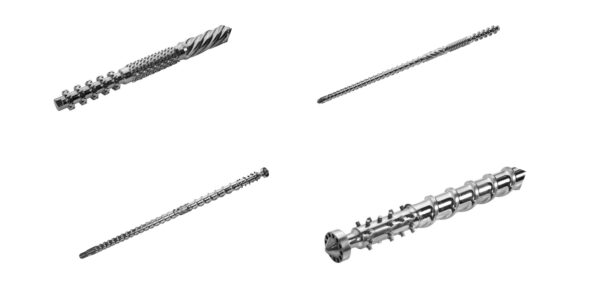

Φ25-Φ250 the screws for Blow film extrusion line

End of content

End of content