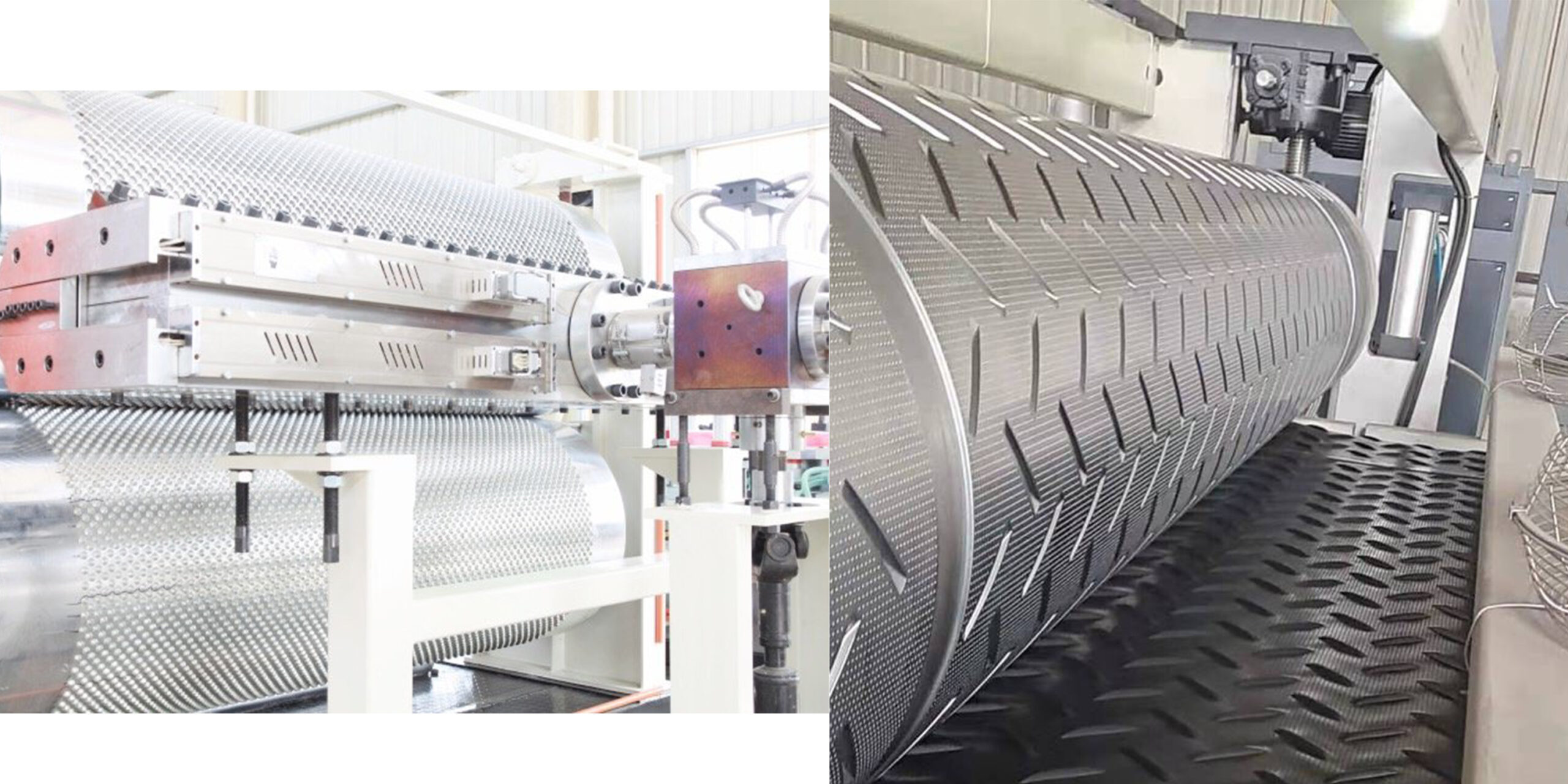

Precision patterned roller

The pattern roller is used for the surface forming treatment of various plastic sheets and plates such as PMMA, PC sheet, PP sheet, etc. The roller surface can be processed into various patterns. The laser electronic scanning and color separation technology is used to convert the customer’s sample image into high-definition digital image information, which is directly input into the engraving machine to copy and carve high-quality roller surface patterns.

Description

The simulation rate of the roller surface pattern is over 98%. Sandblasting shall be carried out on the surface of the roller to make the roller surface achieve the effect of matting, matting, fog, and rough surface according to the mesh size. The products are used in lamps, decoration, leather, automobile, and other fields.

Roller characteristics

1. Roller surface materials can be 45 steel, 38GrMoAl, 42GrMo, 60GrMoV, etc

2. A variety of internal flow channel designs, with uniform roller surface temperature, to ensure uniform product surface patterns

3. The hardness of the surface electroplating layer reaches HRC60-62, extending the service life of the pattern roller.