Showing 1–12 of 16 results

-

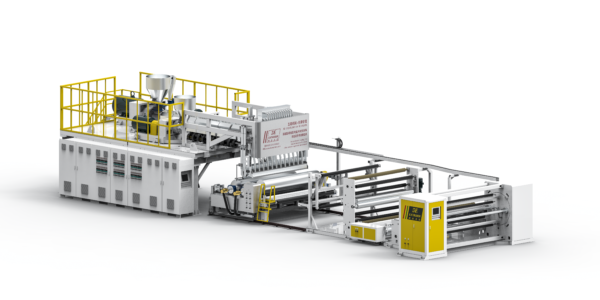

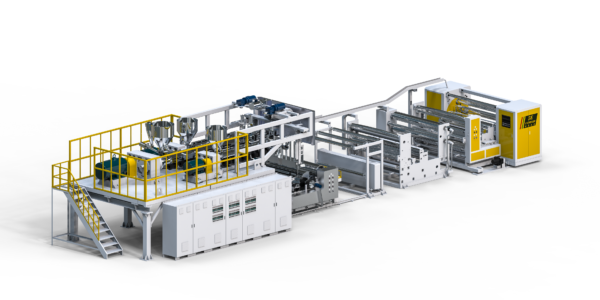

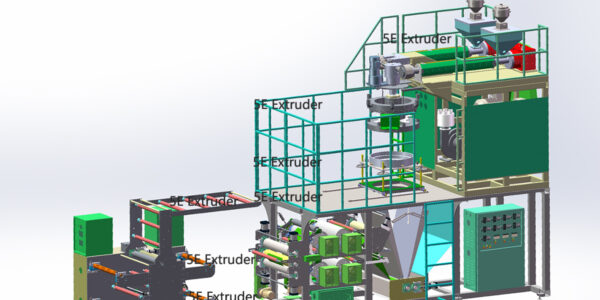

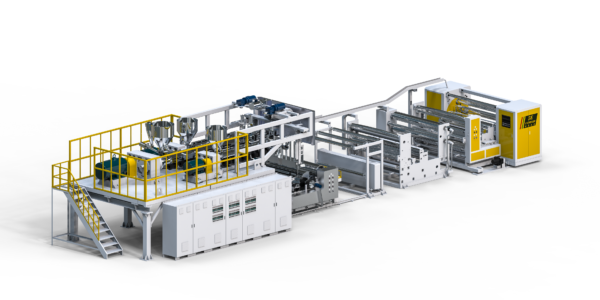

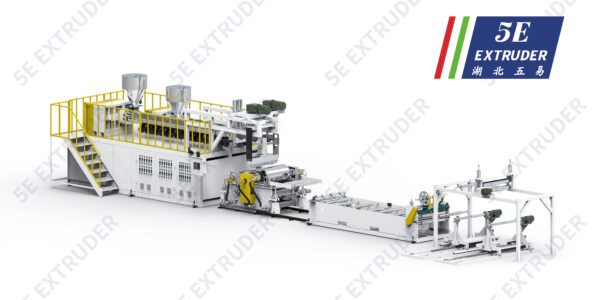

1. Two or more extruders realize coextrusion. The multilayer composite film directly prepared by one-step processing has the advantages of less production process, less energy consumption, and low cost

2. Complete machine PLC control and touchscreen operation

3. The latest designed winding tension control unit ensures accurate, stable, and reliable tension measurement and control

-

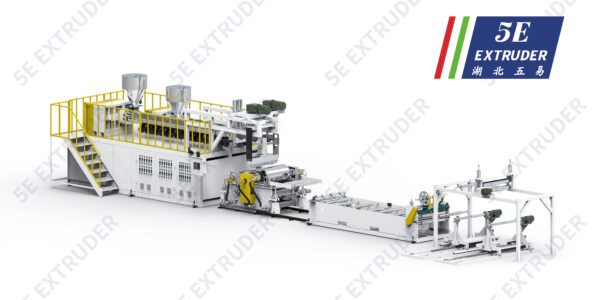

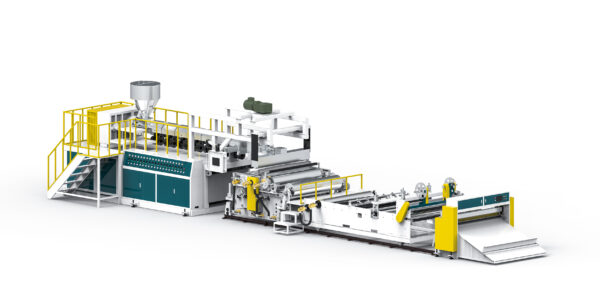

▲The screw is designed with a special mixing function and high plasticizing capacity and is matched with a European static mixer to ensure good plasticization, good mixing effect, and high output

▲Online auto film-thickness measurement and automatic die-head adjusting, imported Europe cooling forming roll is optional, the special spiral runner design ensures good film cooling and shaping effect at high speed

-

Principle of horizontal heating mixer: the heat transfer oil in the oil tank is heated by an electric heating tube, and the materials in the barrel are stir-fried and dried by using this temperature during the mixing process. The interlayer of the barrel is heated quickly and evenly, which is better than direct heating, so as to achieve the purpose of mixing and drying.

-

PE slip sheet extrusion line is mainly used for the production of PE anti-slip sheets, the anti-slip sheet is an ideal replacement for wood and paper pallets.

-

The production line is used for the production of PET and PLA sheets. It does not need a pre-crystallization drying system and is suitable for the production of secondary materials. It has the characteristics of high output, low energy consumption, and excellent plasticization

-

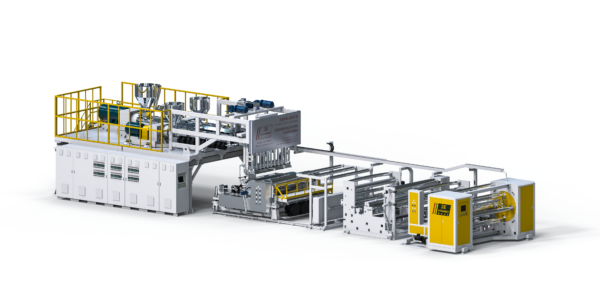

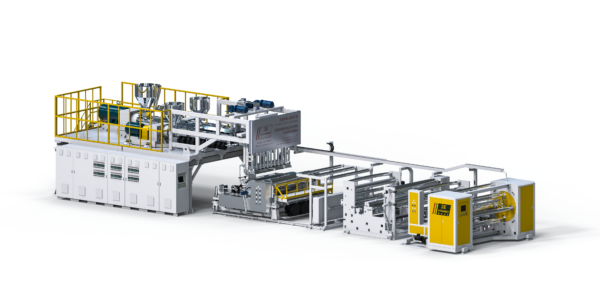

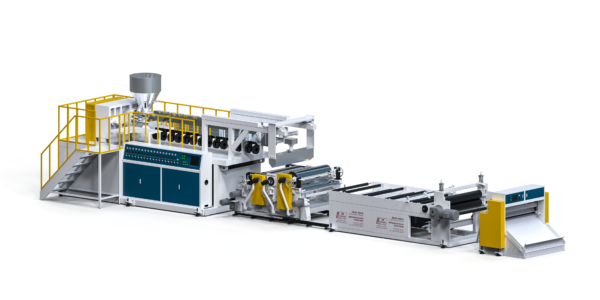

1. Equipped with a positive pressure device to ensure the stability of the film

2. The film online recycling device greatly reduces production costs

3. Fully automatic central rolling, equipped with servo wheel controller, automatic roll changing and cutting, easy to operate

-

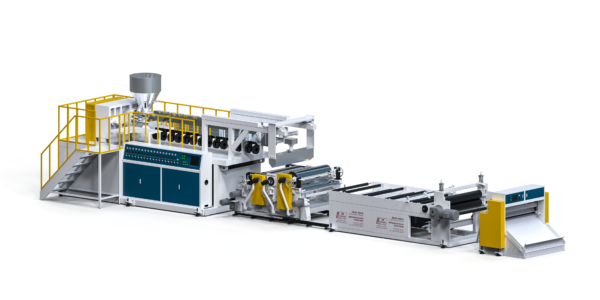

1. The screw is designed with a special mixing function and high plasticizing capacity, which is matched with a European static mixer to ensure good plasticization, good mixing effect, and high output

2. Online auto film-thickness measurement and automatic die-head adjusting, imported Europe cooling forming roll is optional, and the special spiral runner design ensures good film cooling and shaping effect at high speed

-

- Blow-up ratio: 1:5

- The structure of a step-less variable speed reduction gearbox is simple and can be equipped with V.S Motor or DC motor or variable frequency motor according to the customer’s needs to adjust the screw speed at will.

-

The machine can effectively use the proportion of stone powder, which not only reduces the cost of raw materials but also improves the degradability of sheets and ensures the comprehensive physical properties and subsequent processability of sheets.

-

1. Blow-up ratio: 1:2.5

2. The structure of a step-less variable speed reduction gearbox is simple and can be equipped with V.S Motor or DC motor or variable frequency motor according to the customer’s needs to adjust the screw speed at will

-

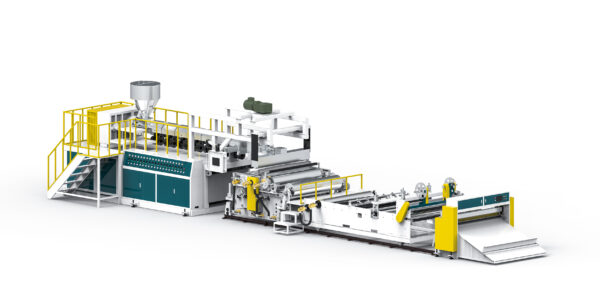

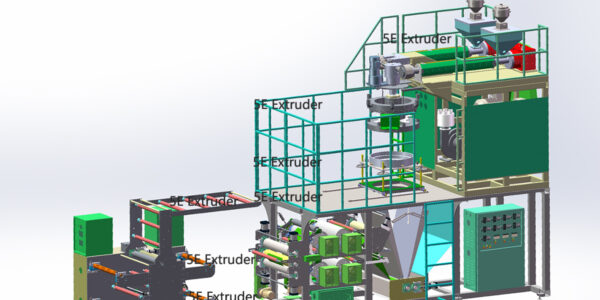

1. Interlocking safety design ensures the safety of operators

2. Equipped with three screws and an optimized combination of the aspect ratio

3. Speed frequency conversion control and touchscreen control

4. Equipped with three in one water tank to save energy and reduce consumption

5. The cutting table adopts a servo motor and swing bar structure to ensure accuracy and speed

-

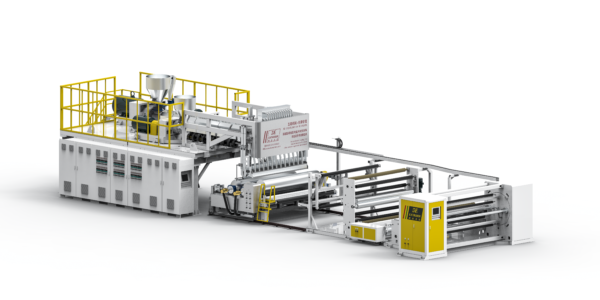

PP PE PS extrusion line has the advantages of high output, good plasticization, convenient operation, and stable operation.

End of content

End of content